Plot 4/149 Onions Complex

Area 4

(Behind Cafe 92)

Lilongwe

Weekdays: 07:30h - 16:30h

Saturday: 08:00-12:00h Collections only

Sunday :Closed

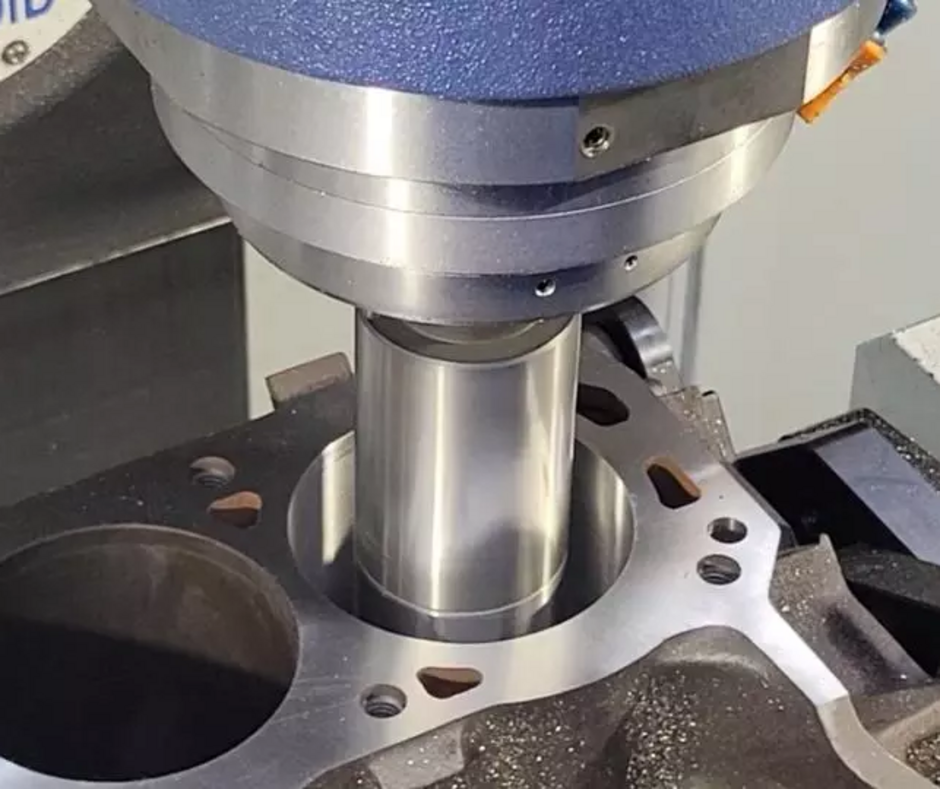

At Crest Engineering, we specialize in providing top-tier machine shop services with state-of-the-art automated machining tools designed for precision and efficiency. Choose Crest Engineering for expert craftsmanship, cutting-edge technology, and a dedication to keeping your engines and mechanical systems running smoothly.

Cylinder Head services:

Aluminum Head Basic Valve Grind and Resurface

Iron Head Basic Valve Grind and Resurface

Resurface, Mill Intake and Deck, Angle Mill

Install Hard Valve Seats

Valve guide resleeving

Welding of Aluminum Heads

Performance Valve Grind

Angle Valve Grind

Machine Guides for PC Seals

Machining of deck surfaces

Custom boring with and w/o torque plate

Custom honing with and w/o torque plate

Align boring and honing of block mains

Aluminum Welding: Ideal for projects requiring aluminum materials, providing strong and clean welds.

Stainless Steel Welding: Suitable for food and medical applications due to its cleanliness and corrosion resistance.

Carbon Steel Fabrication: Commonly used in structural applications, TIG can create precision welds.

Thin Material Welding: We have TIG welding which is excellent for thin materials, ensuring minimal distortion.

Repairs: Fixing damaged metal parts and structures, preserving original strength.

Custom Fabrication: Creating unique parts or assemblies tailored to specific customer needs.

Automotive Welding: Used for vehicle repairs, including chassis and exhaust systems.

MIG and Stick Welding Services: We also offer MIG welding processes for versatility.

Turning Operations: Precision shaping of cylindrical parts, including diameters and lengths.

Taper Turning: Creating tapered sections on workpieces.

Facing: Providing a flat surface at the end of a cylindrical workpiece.

Threading: Cutting internal and external threads according to specifications.

Boring: Enlarging existing holes for precision fit.

Drilling: Creating holes in various materials.

Cut-Off Operations: Cutting specific lengths from larger stock materials.

Custom Piece Fabrication: Producing one-off components tailored to specific needs.

Milling Machine Services:

Milling Operations: Creating flat or contoured surfaces, slots, and grooves in parts.

Face Milling: Cutting flat surfaces perpendicular to the milling cutter.

End Milling: Producing complex shapes and contours with end mills.

Drilling: Creating accurate holes in various materials using milling tools.

Keyway Cutting: Cutting slots for keyways in shafts.

Surface Contouring: Shaping workpieces with complex contours.

Custom Fixture Fabrication: Designing and creating fixtures for specific machining tasks.

Prototype Manufacturing: Developing prototypes for testing and validation.

Combined Services:

Assembly: Combining lathe and milling operations for comprehensive part fabrication.

Repair Services: Fixing and refurbishing parts using both machining processes.

Custom Fabrication: Offering tailored solutions for unique projects requiring both turning and milling operations.

Workshop Manager

Machinist

Turner

Welder

At Crest Engineering, customer satisfaction is at the heart of everything we do. Our clients consistently praise the precision, reliability, and professionalism we bring to every project. From flawless engine machining to expertly crafted welds and custom machining, the feedback we receive reflects our commitment to excellence.

Pressure Testing

Best Price!

Cylinder Head

Engine Block

Hydraulic Cylinder

Custom Fabricated Tanks

Engine block and cylinder head skimmming

Competitive Prices!

Initial Inspection

Preparation for Machining

Determining Skim Depth

Machining Process

Final Inspection

ENgine block reboring and honning

Special Opening offer!

Initial Inspection and Measurement

Determine New Bore Size

Install and trim the New Sleeves

Honing Process

Final Inspection and Assembly Preparation

Step into the heart of our operations with a showcase of the cutting-edge machinery that drives our success. At Crest Engineering, we pride ourselves on utilizing state-of-the-art equipment to deliver precision, efficiency, and unmatched quality across all our services. Our gallery features advanced CNC machining tools, precision boring and honing machines, high-performance welding equipment, and heavy-duty lathes. Each machine is meticulously maintained and operated by our experienced team, ensuring that every project, from engine rebuilding to custom fabrications, meets the highest industry standards.